PVC is a thermoplastic made of chlorine (derived from industrial grade salt) and carbon (derived predominantly from oil / gas via ethylene). It is less dependent than other polymers on crude oil or natural gas, which are nonrenewable, and hence can be regarded as a natural resource saving plastic, in contrast to plastics such as PE, PP, PET and PS, which are totally dependent on oil or gas. This chlorine gives to PVC excellent fire resistance: when PVC is set on fire, the flames go out as the fire source is removed due to the material’s self-extinguishing properties.

PVC pipe is one of the safest and most tested materials used in North America. For over 60 years, every aspect of its production, use and disposal has been evaluated and approved by government and independent certification and testing agencies.

PVC is approved for use around the world in water distribution and transmission, consumer products and medical applications. It is so safe that it is used for intravenous medical tubing, and it is the pipe of choice for ecologically sensitive environments like salt water aquariums, which must use the most inert and safest pipe materials available.

Claims that it’s toxic have been refuted by the scientific community. The evidence shows it neither leaches toxic chemicals like lead, cadmium, BPA or plasticizers; release harmful organotins; pose major hazards in its manufacture, use and disposal; create a dangerous bio-film; nor form dioxins as water passes through, etc.

Moreover, it’s impossible for PVC pipe to leach plasticizers, BPA, lead or cadmium, since these aren’t even used in its manufacture nor are they part of its compound.

Uni-Bell PVC Pipe Association

(Published in Summer 1990 Edition of the Uni-Bell PVC Pipe News)

PVC was discovered as early as 1835, but the first definite report of the polymerization of vinyl chloride did not come until about 35 years later. At that time, the material was reported to be an off-white solid that could be heated to 130 degrees C without degradation.

PVC remained a laboratory curiosity for many years, probably because of its intractable nature. The polymer was inert to most chemicals and very tough (strong). These properties eventually led scientists to consider PVC for applications where durability and toughness were desirable.

In 1912 the first industrial developments were initiated in Germany. Throughout the 1920s, attempts were made to use PVC copolymers that were easier to process than PVC. These early attempts were only marginally successful.

By 1932, the first tubes made from a PVC copolymer were produced. Nearly three years later the first PVC pipes were produced using a roll mill and hydraulic extruder. This two-step process involved melting the PVC powder on a roll mill and rolling the sheet produced up to a billet. The PVC could then be processed in a discontinuously working ram extruder to make pipe. This process was adapted from that used for celluloid and was really ill-fitted for PVC. As a result, the products were often of dubious quality. Nevertheless, these early PVC pipes were deemed suitable for drinking water supply piping and waste water piping because of their chemical resistance, lack of taste or odor and smooth interior surface. From 1936 to 1939 over 400 residences were installed with PVC drinking water and waste pipelines in central Germany. Various test pipelines of PVC were laid in Leipzig, Dresden, Magdeburg, Berlin, Hamburg, Cologne, Heidelberg and Wiesbaden during the period of 1936 to 1941.

Both the pipelines for chemicals and those for water supply and waste water came up to expectations, as did the test pipelines in the cities mentioned above, apart from damage caused by World War II. The PVC pipes installed in central Germany are still in use today without any major problems.

Although product developers began to use PVC in a variety of ways – in shoe heels, golf balls, and raincoats, to name just a few – its application increased significantly during World War II.

PVC turned out to be an excellent replacement for rubber insulation in wiring and was used extensively on U.S. military ships. After 1945, its peace-time usage exploded.

In the U.S., PVC's materials are natural gas and rock salt.

Natural gas is heated under pressure to form ethylene. This is called "cracking."

-

Common rock salt (sodium chloride) is split by electrolysis to produce chlorine and lye (sodium hydroxide).

-

Chlorine and ethylene are combined to form vinyl chloride monomer (VCM).

-

VCM molecules are then joined end-to-end (polymerized) to form long chains of Polyvinyl Chloride polymer (plastic).

-

The thermoplastic PVC powder is compounded, melted and extruded into pipes.

Source: (Uni-Bell PVC Pipe Association)

SANIGUARD 8055 DWV Pipes & Fittings

SANIGUARD 8055 DWV Pipes & Fittings

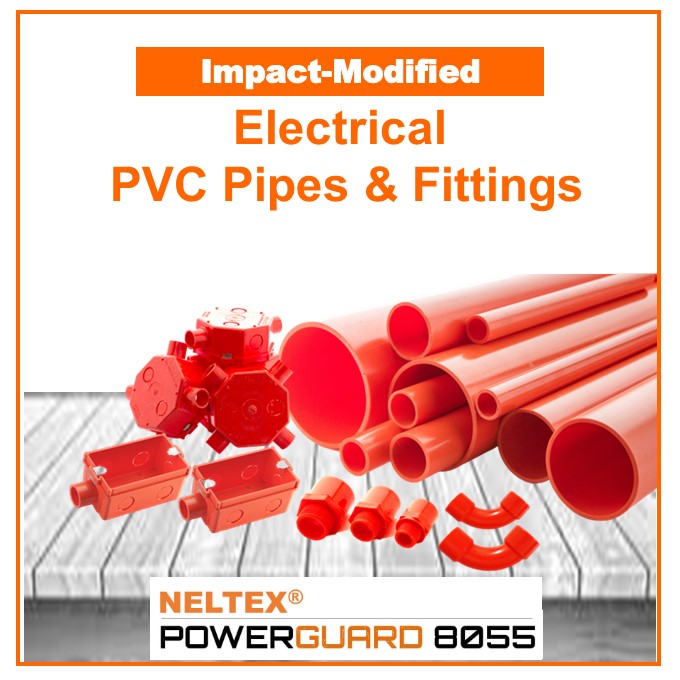

Impact Modified Electrical PVC Pipes and Fittings

Impact Modified Electrical PVC Pipes and Fittings

Quality & Toxicity Tested PPR Pipes and Fittings

Quality & Toxicity Tested PPR Pipes and Fittings

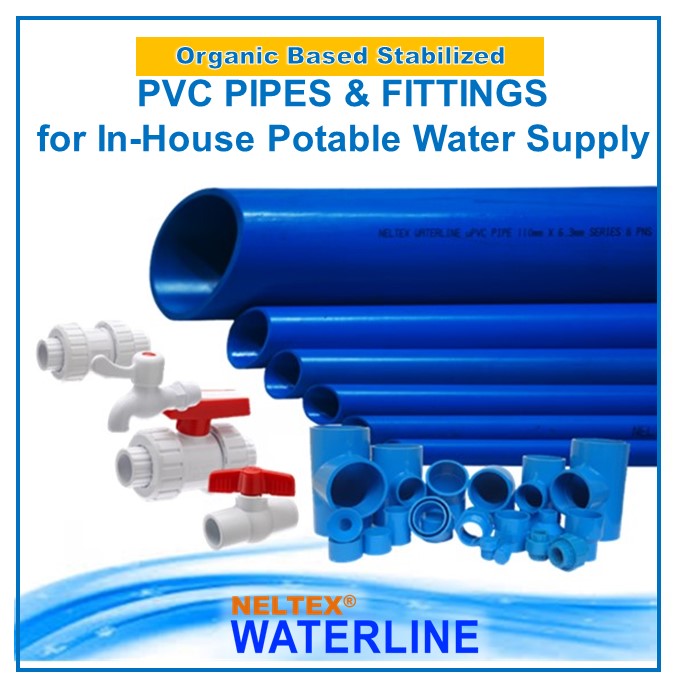

Organic Based PVC for In-House Potable Water Supply

Organic Based PVC for In-House Potable Water Supply

Toluene-Free PVC Pipe Cement

Toluene-Free PVC Pipe Cement

PVC PRESSURE PIPES & FITTINGS with Zero-Gap Machine-Installed Fixed Seal

PVC PRESSURE PIPES & FITTINGS with Zero-Gap Machine-Installed Fixed Seal

K65 Virgin PVC Pipes and Fittings for DWV

K65 Virgin PVC Pipes and Fittings for DWV

K65 Virgin Electrical PVC Pipes and Fittings

K65 Virgin Electrical PVC Pipes and Fittings